cp-e

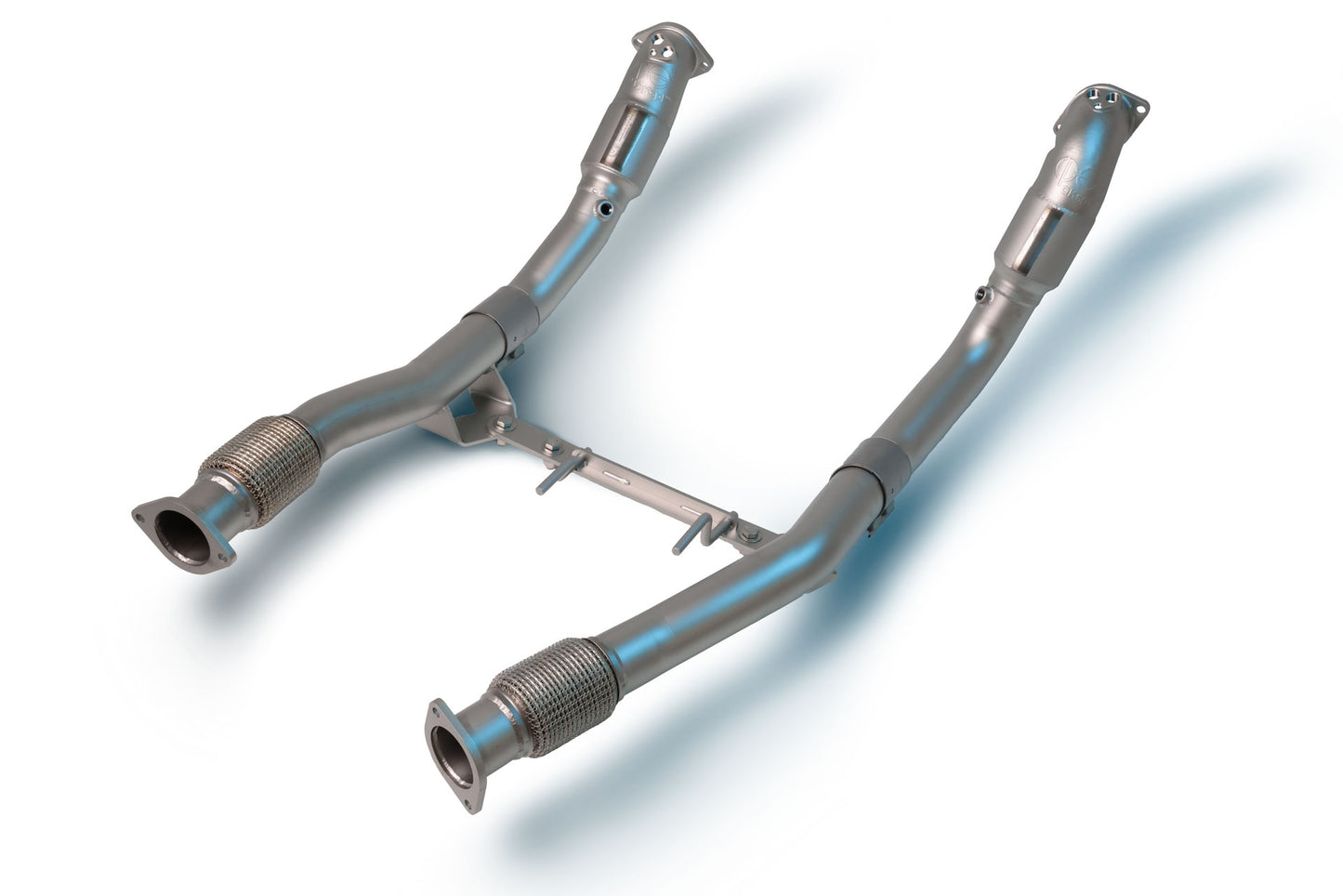

cp-e™ - QKspl™ Cast Bellmouth 3" Downpipes - 2022+ Bronco Raptor

cp-e™ - QKspl™ Cast Bellmouth 3" Downpipes - 2022+ Bronco Raptor

Couldn't load pickup availability

Ford Bronco Raptor Downpipe Features:

- 3.00” Piping

- Only one available with stainless steel, cast bellmouths!

- Includes custom, multi-layer stainless gaskets

- Replaces unreliable factory downpipe

- Fully mandrel bent and formed using state of the art technology

- Extra O2 Bung in casting for Wide Bands

- Titan finished

- Made in the USA

- Limited Lifetime Warranty

PRODUCT DESCRIPTION:

The cp-e® downpipe set for the Ford Bronco Raptor is unlike any other—it’s engineered from the ground up to be the most durable and robust downpipe available for this model. Every design element was meticulously considered, including unique cast stainless bellmouths built to outlast the vehicle itself. These are crafted to be far more durable than a traditional flange and tube setup held together by welding. The design is tailored for an exact fit with the Bronco Raptor, with an upper O2 bung port cast into the structure for optimal placement—a crucial feature given the tight confines of the engine bay and exhaust tunnel. We also included an extra O2 bung in that same casting for those that want to add a Wide Band Sensor to their setup.

Our catalytic converter is brazed to the outer shell’s sidewall to ensure unrestricted airflow, avoiding the conventional stuffed and rolled method that can compromise durability. To enhance strength and improve exhaust flow, we also stamp the endcaps.

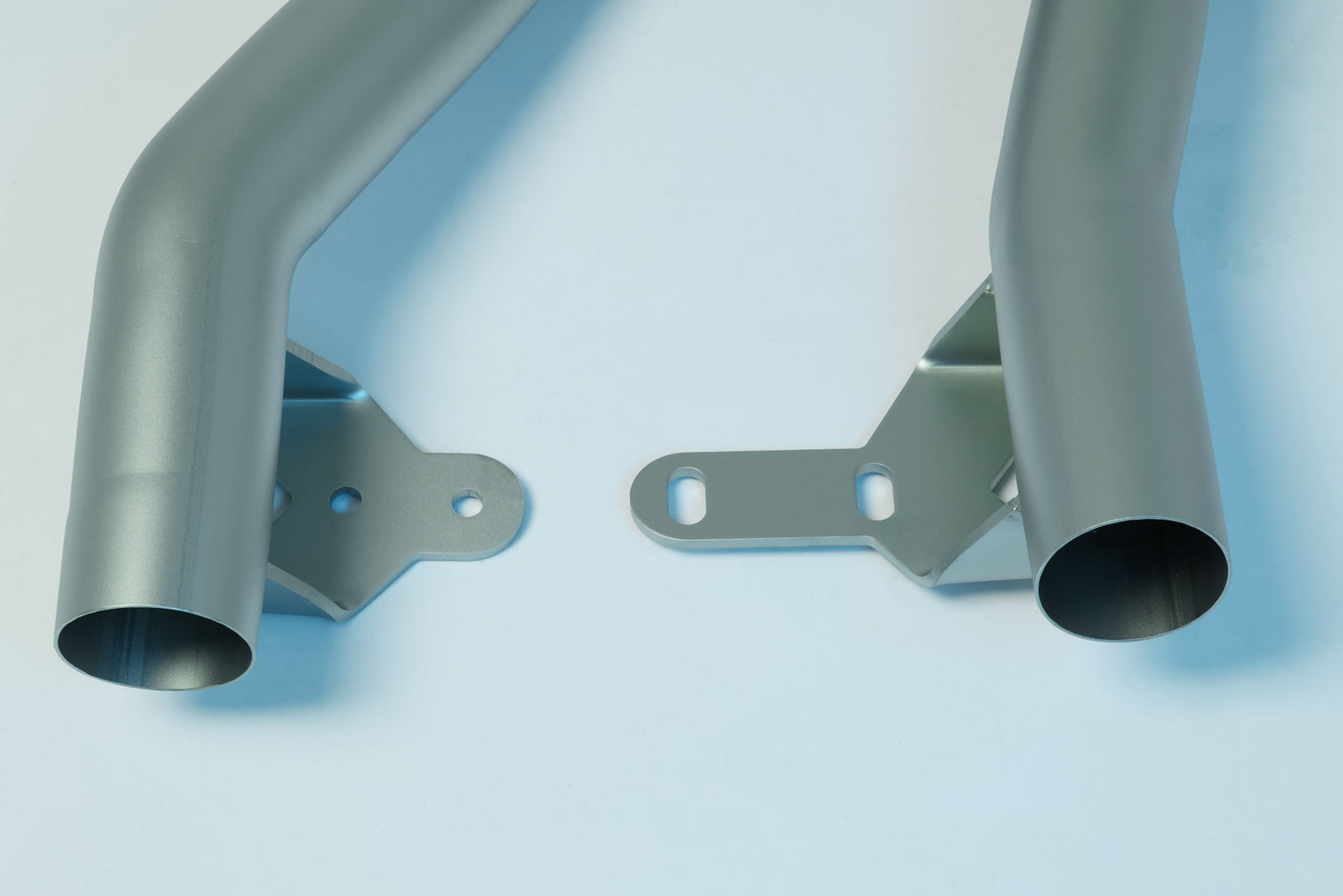

Further down the tube, you’ll find a secondary O2 sensor, precision CNC-machined in-house to achieve an exact fit on the tubing, allowing for superior welding. This sensor is more accessible and doesn’t require casting in place. We mount it with CNC laser-cut brackets produced in-house, setting it apart from those that merely use rods or flat sheet metal. This added attention to detail reflects our commitment to pushing boundaries.

The tubing itself is CNC-bent from 16-gauge stainless steel and formed as a single piece. Using thicker stainless steel than many competitors, we ensure the downpipe can withstand the high temperatures and vibrations typical of this part’s location in the exhaust.

All fixturing and welding are done in-house, with each fixture designed on a computer and set using CAD to ensure consistency. This approach takes more time initially but results in a highly refined product.

With over 20 years in the industry, we’ve handled many exhaust gaskets, but one from a Mazda stood out as the best. Inspired by it, we crafted our own custom, 4-layer stainless steel exhaust gasket. While most gaskets use only two layers, we doubled that to provide the best possible seal. More layers allow the gasket to compress and conform better, resulting in an improved seal. Initially made specifically for the Bronco Raptor, this design will soon extend to all our downpipes!

Not California emissions compliant | No implied CARB certification | Off-road use only

CALIFORNIA WARNING: Cancer and Reproductive Harm – www.P65Warnings.ca.gov

Share